#ARCTIC. #SIBERIA. THIS IS TAIMYR. The first machine builders arrived in the Arctic on July 1, 1935 on the steamer Spartak. The plant began with three lathes, and one machine did not fit in the room and half went out into the street. The beginning of the future Mechanical plant was laid by small repair and mechanical workshops, built in 1936-1937.

The Mechanical plant – one of the oldest enterprises of Nornickel – is a full-cycle machine-building plant, consisting of six subdivisions: two production units and four workshops.

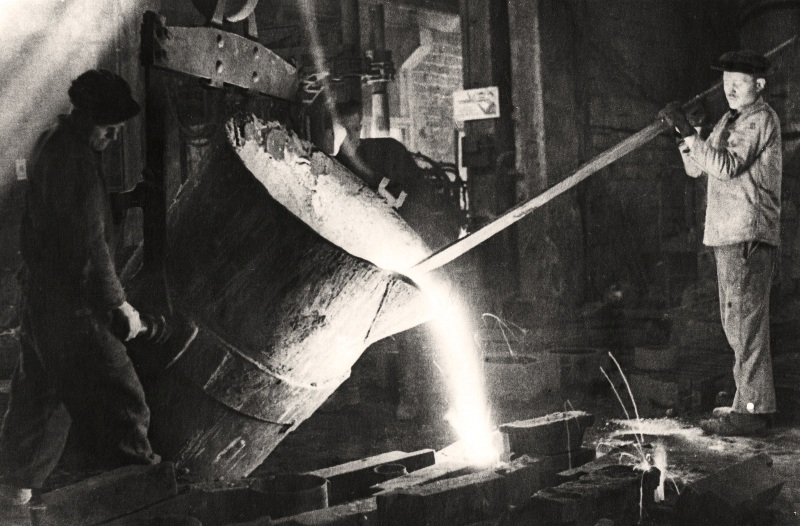

“The plant began with small repair shops, in which there were only two or three machines. And gradually those workshops grew and developed. The first cast iron smelting was carried out on May 25, 1937, in mechanical workshops, and on May 26, the first non-ferrous metal castings were made”, told Vyacheslav Burdyukov, the Mechanical plant’s deputy director for production of Norilsk Providing Complex LLC.

A separate chapter in the development of the plant is the implementation of the project for the plant gasification, which made it possible to reduce the volume of dust and gas emissions by more than 21 tons per year, to exclude untreated sewage effluents in the amount of up to 38 thousand cubic meters per year, to exclude emissions of diesel fuel combustion products into the air of the working area in the plant subdivisions.

At the present time, the Mechanical plant is a developed, diversified modern enterprise with a closed technological production cycle. The uniqueness of the enterprise is its full cycle.

The main strategic objective of the plant is to provide the Nornickel enterprises with spare parts and materials.

“In 2020, we mastered a number of new types of products – quick-release couplings, reinforcing cages, materials for securing mine workings. They also replaced obsolete equipment worth 100 million rubles, carried out repairs with modernization of the main technological one. In 2021, repairs have already been made, and the laundry equipment has been replaced. We have completed equipping production facilities with a warning and fire extinguishing system. Complex replacement of equipment is underway. And also the organization of a new production of materials for mining fastening. This will significantly reduce the negative impact, increase efficiency, and create a base for the development of new types of products. The foundry reconstruction is on the way”, said Aleksey Suchangzhi, the Norilsk Providing Complex LLC Mechanical Plant deputy chief engineer for development.

Now the plant employs about 1000 people. There is no other enterprise in the Norilsk industrial region with a similar set of various working specialties, including unique ones. The plant produces more than 30 types of products – this is about 7.5 thousand tons for 5.5 billion rubles per year.

The mechanical plant covers not only the Norilsk division enterprises’ needs, but also those of Norilsk itself.

“We are often approached by the city administration to make something. This is a unique, creative work. These are, for example, commemorative plaques on Norilsk houses. The memorial dedicated to the Victory in the Great Patriotic War – there is also a cast with the names of our dead Norilsk residents. The most famous welcoming stele on the Norilsk-Alykel road is also a product of the Mechanical plant”, said Vyacheslav Burdyukov.

And also bells for the Golgotha memorial complex, the fence of the Church of All Who Sorrow Joy, memorial complexes in Talnah, a frame for the information board on the company’s Norilsk division building, cast decorative fences for separating lawns on Leninsky prospekt, fountains, playgrounds, Kisses Bridge on the Lovers’ Alley and much more that adorns the city’s streets and squares.

Follow us on Telegram, Instagram and Facebook.

Text: Angelica Stepanova, Photo: Marina Peshkova and the Nornickel Polar Division archive