To improve production efficiency, the Copper plant of the Nornickel Polar Division has begun testing a method for the production of copper cathodes, which will additionally produce up to 700 tons of pure copper per year.

The new method was proposed by the director of the Copper plant Alexander Leonov and the head of the copper electrolysis shop Mikhail Shilovsky. The technology point lies in using copper cathodes rejected due to appearance and chemical composition in secondary electrolysis. But they will act as anodes dissolving during electrolysis.

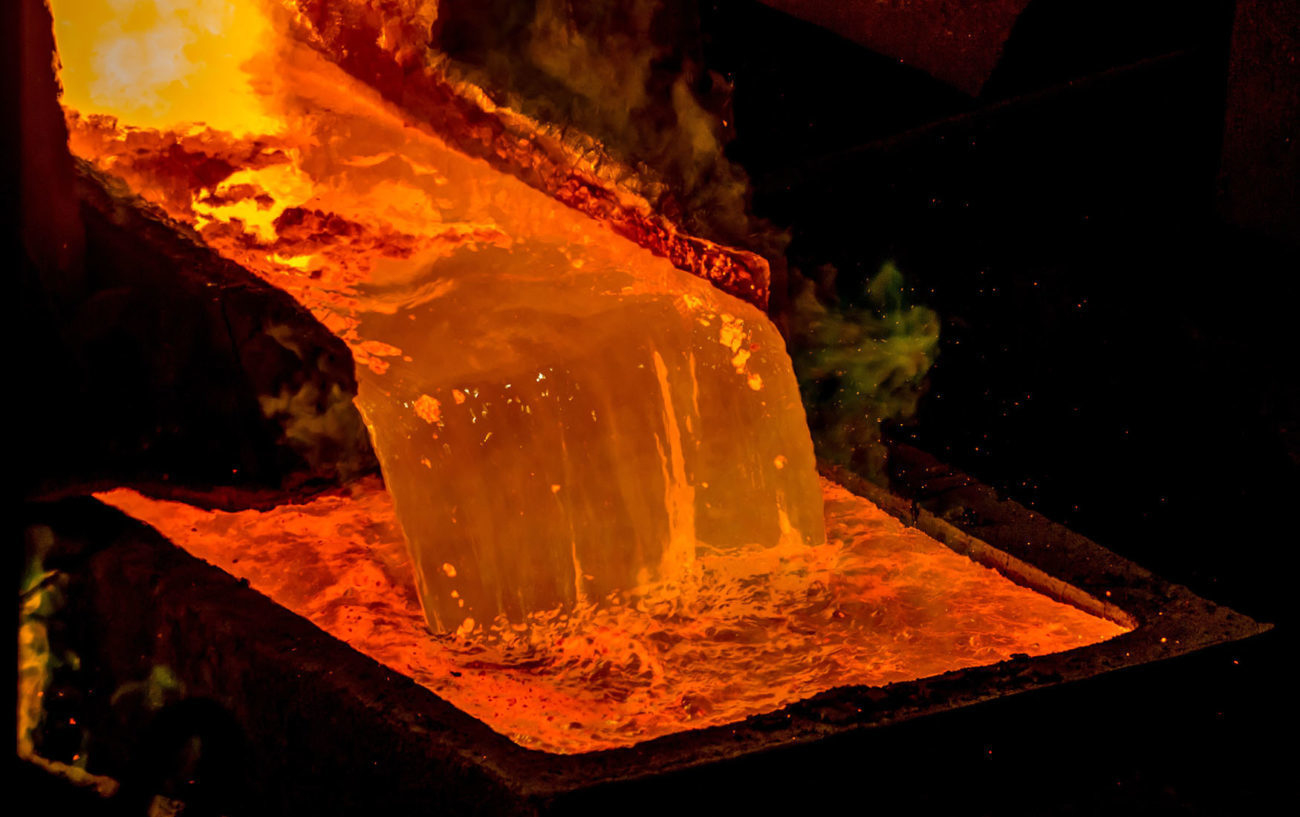

As the Polar Division’s press service explained, previously the discarded copper sheets (cathodes) with an average weight of 70–80 kilograms used to be sent for resmelting, so that they would become cathodes in the composition of the so-called anode copper. But that was quite labor and time demanding and ineffective.

The new method has not required any investment. One of the electrolysis bath units at the plant was reequipped for the new process. The tests will allow to work out the processing method, select the optimal electrolysis modes in new conditions, and get rid of shortcomings.

The use of this method for processing substandard cathodes will increase the productivity of the workshop and the plant as a whole. The enterprise annually produces about 300 thousand tons of cathode copper, which is shipped to consumers around the world.

Text: Tatiana Ermolaeva, Photo: Rostislav Zolotaryov, Marina Peshkova