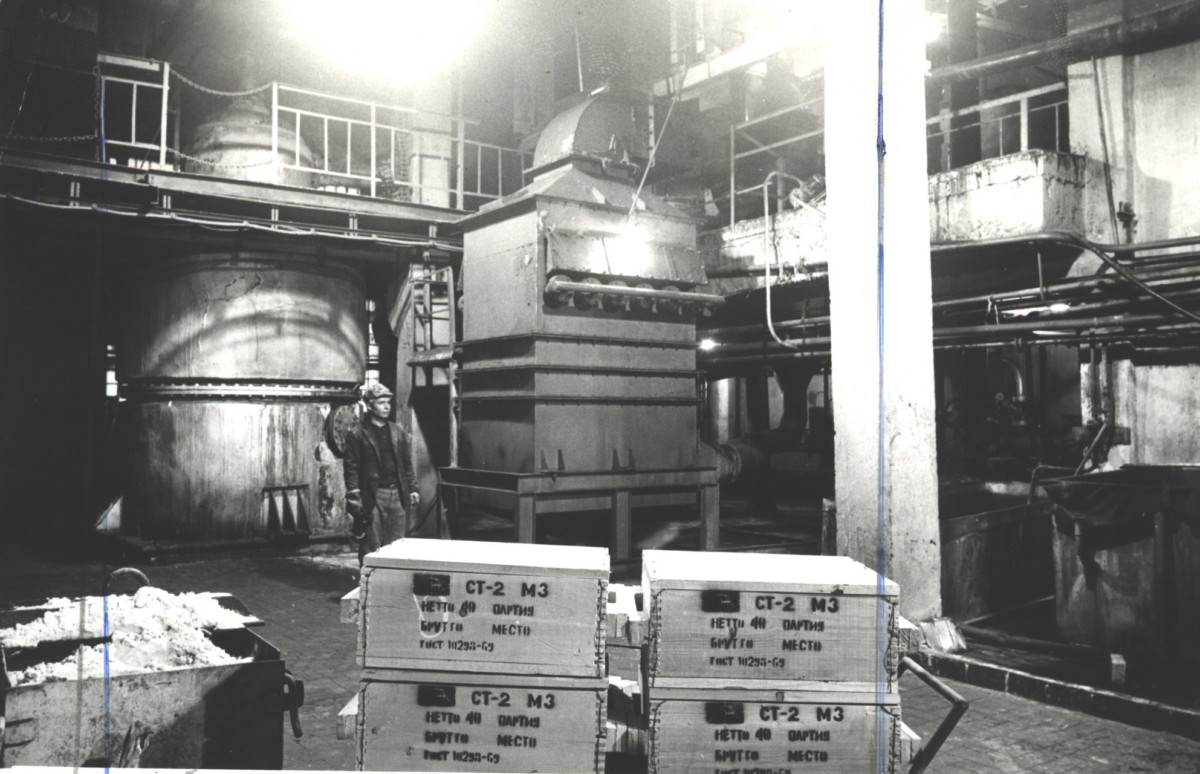

#ARCTIC. #SIBERIA. THIS IS TAIMYR. In 1958, the plant No. 26, as a structural production unit, became the metallurgical shop of the Copper plant. MS-1 was built to replace the sludge plant, located at the opposite end of the city, on the industrial site of the Nickel plant.

In 1966, the process of extracting iridium from spent electrolyte was mastered. In 1978-1979, processes for extracting silver from solutions were introduced. In 1992, the tellurium production process was set up. In 1997, a process for the production of granulated silver was introduced.

Until 2016, the metallurgical shop processed nickel and copper sludge from electrolysis shops. The first came from the Nickel plant, the nickel electrolysis shop, the second – from the copper electrolysis shop of the Moscow plant. After the Nickel plant closure, only the copper sludge processing remained in the metallurgical shop.

The peculiarity of the electrolysis shops’ sludge products is that they concentrate the most valuable and rare components, which initially come into production in the ores of the Talnah and Norilsk deposits. These are platinum and palladium, the so-called satellites – rhodium, iridium, ruthenium, osmium; noble metals – gold and silver, as well as such rare elements as selenium and tellurium.

The purpose of the workshop, as well as its technology, is precisely to concentrate such elements and to produce products from them with a rich content. Some of the products are produced in the form of precious metals concentrates, and some – in pure form, these are by-products – selenium and tellurium.

In the History Spot photo project previous publication, we told that Fedorovsky street in the Talnah district of Norilsk was named after the author of the first Soviet textbook on mineralogy.

Follow us on Telegram, VKontakte.

Text: Svetlana Ferapontova, Photo: Nornickel Polar Branch archive